With more brands and choices available than ever, make sure you're using the right glove for the right task.

Are you buying the wrong gloves at the right price?

Did you have to settle for lesser quality gloves during supply chain disruptions?

Those days are over.

As the surplus of low-quality gloves dwindle, now is the perfect time to reevaluate your hand protection options.

Choose the perfect fit for your application

Do you need powder free nitrile? Wondering which AQL levels or colors is right for your project?

With 3,000,000,000 disposable gloves sold, and over 30 years of industry experience, let us help you navigate the maze.

Primary Glove Materials

Nitrile Gloves

Are you looking for latex-free gloves? Nitrile is for you with superior durability, minimal allergies, and a comfortable fit for various applications.

Why choose nitrile?

It's not only cost-effective but also versatile. While it may lack the elasticity of latex, nitrile advancements has come a long way in providing fit and dexterity for many applications. Nitrile excels in resisting petroleum-based oils and fuels, offers outstanding puncture resistance, and allows for easy detection of tears before you handle hazardous substances. Plus, it's heat-tolerant and eliminates the risk of latex allergies.

Latex Gloves

Latex gloves offer a snug fit and excellent elasticity, making them the go-to option for tasks requiring maximum finger dexterity.

When is latex the best choice?

They are the ideal choice for medical or precision applications that require a high level of form-fitting, tactile sensitivity, and effective protection against blood borne pathogens. If you are concerned about allergies or need protection against harsh chemicals, consider nitrile gloves as an alternative.

Neoprene Gloves

Neoprene gloves are highly resistant to chemicals, oils, and a wide array of corrosive substances, making them an excellent choice for various industrial and laboratory applications.

When to choose neoprene?

These gloves are your best bet when you need the snug fit and dexterity of latex but want to avoid allergy risks. Effective against a wide range of acids, peroxides, and harmful chemicals, they are a solid choice for high-precision tasks, including medical procedures. However, it's worth noting that they aren't the best match for certain aromatic hydrocarbons and tend to be pricier than nitrile and latex gloves.

Vinyl Gloves

The budget-friendly, latex-free choice for a wide range of applications.

When are vinyl gloves the best option?

Vinyl gloves excel in scenarios that don't require a snug fit—think basic food prep or industrial tasks involving oils, fats, resins, and greases. They hold up well against abrasions, remain flexible in cold temperatures, and have anti-static qualities. If latex allergies are a concern, vinyl is a safe bet. However, they're not recommended for jobs requiring protection against hazardous materials.

Polyethylene Gloves

These gloves are your go-to for short-term applications where sanitation is key but high-level protection isn't necessary. While they can't match the dexterity and robust defense of other materials, they excel in convenience and affordability.

Glove Grades

Medical (Exam) Grade:

Medical grade gloves are precision-made to meet strict healthcare standards, providing reliable barrier protection and dexterity for healthcare and lab professionals in infection control and medical procedures.

Industrial (Non-Medical) Grade:

Industrial or B grade gloves are designed for use in various nonmedical applications, offering durable hand protection in industrial and commercial settings.

Chemo Gloves

Chemotherapy-approved medical grade gloves must meet ASTM Standard D6978-05, which entails rigorously testing against nine specific chemotherapy drugs for assured permeation resistance.

Glove Sizes

Wrap a measuring tape around the widest part of your dominant hand, just below the knuckle and excluding your thumb

We offer a wide range of sizes, from XS all the way up to XXXL.

Cuff Length

Cuff length is measured from the tip of the middle finger to the cuff’s end.

Packaging

Thickness and Strength

MIL is the standard unit of measurement for glove thickness.

Tensile strength is the amount of force in MPA (pounds per square inch) needed to stretch a medical glove until the breaking point

Elongation measures glove thickness and indicates how much a glove can stretch before breaking.

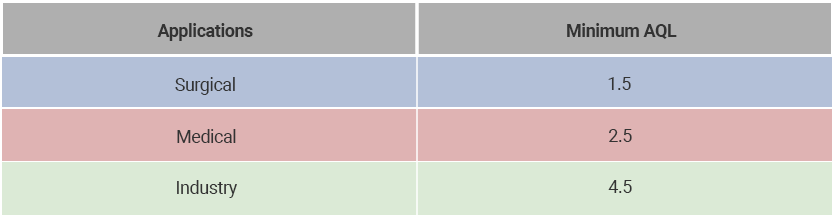

AQL

The AcceptableQuality Level (AQL) is a key industry standard that measures the average percentage of defective gloves in a sampled batch. A lower AQL indicates a higher-quality product with fewer defects.

Tensile Strength is the amount of force in MPA (pounds per square inch) needed to stretch a medical glove until the breaking point

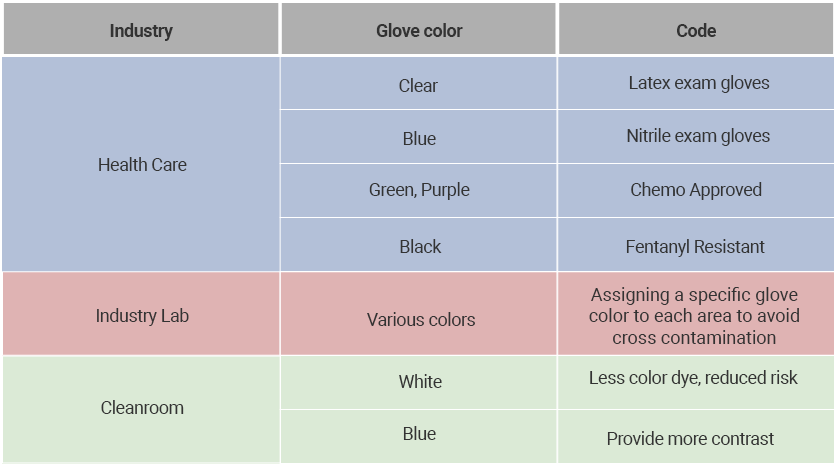

Color

Popular glove color codes by industry

Applications & Industries

EMS and Fire

High-risk scenarios call for thicker gloves with long cuffs

Jails, Police, and Detention

Medical Labs and Clinics

Food Industry

Gloves Terminology

AQL level: Acceptable Quality Level

High-risk scenarios call for thicker gloves with long cuffs

MIL: unit of measure for the thickness of gloves

Glove Weight: Since thickness can vary throughout the glove, weight can be a more reliable indicator of the amount of material (m.g.)

Plasticizers: Chemical components added to nitrile or vinyl gloves to improve elongation and overall fit

Powder Free: Powder removed through a chemical washing process called chlorination process. Limited Powdered Latex Gloves are available for easier donning.

Textured Finish: Gives you a better grip and can be found on fingers (usually more textured) or the whole glove. Good for wet applications.

Diamond Textured: Gloves with a raised diamond shaped texture throughout the exterior surface of the glove. This provides 60% more surface area to channel away liquids for a firmer grip.

Glove Color: You may choose to color code by material to quickly identify latex versus nitrile or by department to avoid contamination.

Donning: The act of putting on a glove. Nitrile gloves have a lower resistance to friction than latex gloves, making them easier to don and remove. In addition, finishes are added during the manufacturing process to improve donning.